LEGO LESSONS FROM ENGINEERING FIRM CEO

By Frank Bennardo, PE January 7, 2020

PART 1: THE SETUP

It began when I walked by the newly opened LEGO® store at the local mall (it actually started when I was 5, but we’ll get back to that). A cool new LEGO® crane model in the window caught my eye and it ended up as a gift to me from the Engineering Express® Staff for the

holidays. I assembled it during the Christmas break with my wife and son (my wife being the obvious catalyst in all of this) and I found myself flooded with feelings from my childhood. For hours I was in a peaceful, focused state, far from any of my distractions of electronics and other activities of the day. See, I was (am) the king of LEGO®’s growing up (as many engineers would tell you) and this LEGO® building exercise triggered a series of emotions in me that paralleled much of my work today.

I proudly displayed the model at the office which my wife put on Instagram and spawned more views and followers than any other topic we posted. We wondered how we could have missed such a strong connection between LEGO®’s and the construction industry we serve? We had the idea to compliment the model at the office with some extra LEGO® parts for our office and guests to build. This is where the fun began.

KING OF LEGOS

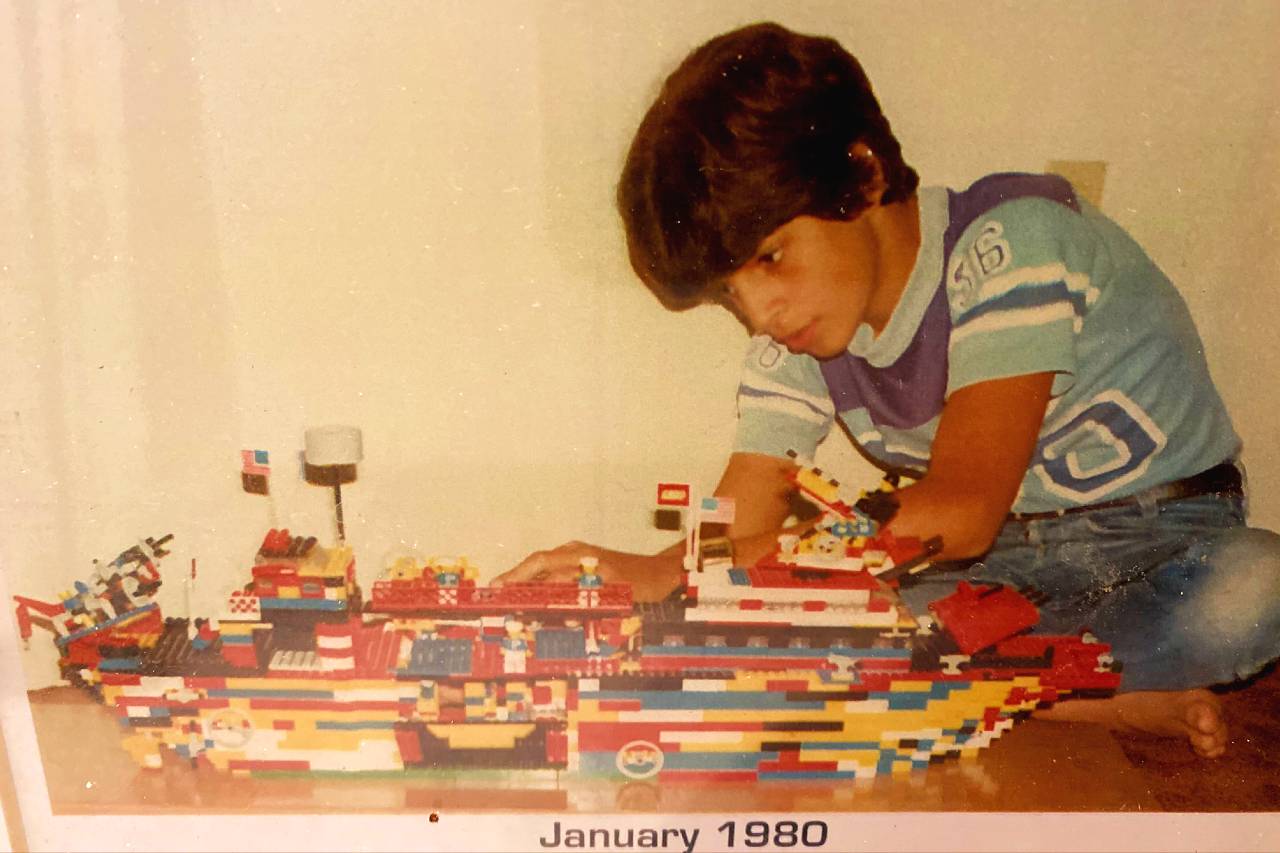

Yes, I said I was the king of LEGO®’s, and not just any LEGO®’s, ‘Expert’ LEGO®’s as they called them at the time (now referred to as Technic). Nobody told me back in the day that you were supposed to actually ‘build the models’, and certainly not keep them assembled after they were built, so I became obsessed with figuring out what I could build with the pieces as they were added to my collection. I collected set after set competing with my cousin’s collection (he wound up giving me his) and built bigger and bigger working models of things like a working crane game, functioning gumball machines, auto pin resetting marble bowling alleys, multi-function battleships (pictured) and the list goes on.

Add those LEGO’s to all those collected with my son (he’s now 26) and I had stored away a huge collection (5 large tubs in the garage). The idea was to curate the ‘best of the best’ from the 5 boxes into the ‘ultimate Expert LEGO® set’. I wound up getting much more than I bargained for.

PART 2: CURATION

You see, as I was sifting and sorting through the LEGO®’s, hour after hour thorough the many years of history, I couldn’t help noticing the parallels between LEGO®’s and our growing company. And it all comes down to Mise En Plas. (we’re getting there).

First was to figure out what container to use to store the ultimate pieces. I bought 2 shoe box size clear containers and found myself being overly-selective with the pieces I was choosing for such a small collection, no different than not curating the proper resources at work to get the job done.

I noticed pieces that were distractions to the goal. They were taking my focus away from what I was trying to achieve. I had to set up rules on what constituted the perfect and ‘inspiring’ pieces and remain vigilant with what didn’t fit, tougher to do than I thought. How does that fit in my work life I thought?

I knew I could buy larger compartmentalized containers to sort out all the variety of pieces to most efficiently curate my ultimate LEGO® set so I continued the collection process without worry of how it would turn out in the end. It was another lesson, the resources are out there to achieve your potential.

I decided to limit the colors selected for the set to those truly Technic (and coincidentally our new office colors, yellow, black, and gray – or was it?) – Back when I was younger I didn’t care about the colors I built with. But now I see the benefits, plus I had the pieces, it was just a little extra effort, another lesson learned – make the extra effort to do things right.

So I’m sifting and collecting, area after area. After I was certain I had everything I wanted and stood up something interesting happened. I looked down at the LEGO®’s and pieces that didn’t see up close came into focus. It was another parallel for me, stepping away to see the bigger picture from another perspective.

There were also times when I started looking for specific pieces to add to the collection. Oddly enough, when I focused on just that piece in the pile, more and more would appear. The rule winds up applying to work as well, less distraction leads to more productivity with focused work.

I kept saying to myself I have enough for my collection but found myself drawn to look for more. When was it enough? I had to commit to a stopping point, no different than my life today always searching for more, or meetings that run too long, projects we shouldn’t take, and unnecessary risks taken.

After going through my tubs I had collected enough pieces to assemble them into their new home.

PART 3: SORT & FILTER

If you played LEGO®’s and stored them away over the years, you know that you never fully disassemble them to put them away. There are always semi pre-built model ‘chunks’ floating in the piles. Each chunk had some piece gems and some parts that didn’t meet my part criteria. I found myself wondering if it was worth it to spend the time taking them apart to get to the gems, no different than putting that extra effort at work to get something right. Technic sets are not easy to take apart but in the end I’m so glad I did, it was a much better project than if I took the more lazy route.

With my pieces all apart and in front of me waiting to be placed into the many compartments, I was faced with many questions – Do I filter by color? (I originally thought so but that didn’t work), by each piece type? (would have been over a hundred) How do I best group parts for optimal use and restocking? This reminded me of how we’re segmenting our resources at the office – Do we store resources by material, department, training vs templates, calculators, etc. for ideal use and scale?

This turned out to be the pivoting point in the whole project. Do this right and you have a system that can expand, help create, inspire, and produce incredible results by maximizing productivity. Get this wrong and I’d be re-filtering, searching, getting distracted and losing interest. It was at this moment that I recalled what my cousin Chef Andrew taught me in his cooking school – Mise-En-Plas. The chef that’s prepared can cook creatively for hundreds. Spending time cutting the onions when the customer is waiting will quickly get you behind. This is exactly the premise that’s building Engineering Express®. Our core goal is to create Engineering Mise-En-Plas (everything in its place) and the rest follows. Too many times we think we’re too busy cooking for the customer to prepare for the next meal and wind up playing catch up. I couldn’t wait to return to the office to optimize our setup for more efficient production.

I didn’t get it all right the first time either, but I was focused and created rule sets which I refined and tested. Should I group all the connectors together or group them by size? Put the straight connectors with the L connectors? I had to be able to adjust and not stick to habits I was forming, just like at work. What wound up working is asking myself how would I find a piece if I were building something? I wondered how that question translated to our office workflow.

Halfway through my sorting & filtering I noticed I was making mistakes. You know, putting the L’s in with the straights. I had no quality control process and there were many distractions that took me away from the project, both of which we face at work as well. I had to invent a LEGO® sorting Quality Control system.

My wife had come over to help at one point. I gave her a brief description of what to do and when I came back from walking the dog I found she did what was instinctual not what I expected because I did not give her clear instructions. It’s the important lesson to take the extra time to teach, document, clarify, and monitor someone you’re giving instruction to and not rush off assuming everything’s going to be the way you want it to – it won’t. It took twice as long to redo what she did, lessons learned.

As I approached the end of my filtering process I noticed I had to make adjustments. Some containers were overfilled and some were mostly empty. Move the gears to 2 slots? Sort them if I do? It’s being able to make adjustments to your process and not clinging to your wrong decisions made that makes one agile enough to adapt to changing conditions.

PART 4: DELIVERABLES

I finally get everything assembled and gaze at my new masterpiece and realize just how valuable this has become to me. It was surely greater than the sum of its parts no different that Engineering Express® is greater than each employee alone. We’re a unique organization with a necessary place in our industry, a huge responsibility. I started doubting bringing the finished product into the office. Maybe it would be better off at home? But that’s exactly what LEGO®’s are for- to be played with, admired, to build and create.

It’s no different than one’s engineering license. For those with an engineering degree and perhaps even a Professional Engineering license, it is why we became who we are. LEGO® models are not meant to collect dust on the shelf, LEGO®’s are meant to be played with. Equally, it’s a disservice to our profession not to make the most of your engineering career and step up and take responsibility for your own design (engineers can become PE’s and certify their own work). How many doctors do you know go through all that schooling and training and never help a patient themselves?

I realized that bringing the sets to work would be a liability. I had to put safeguards in place, no different than protecting Engineering Express® with proper insurances, computer backups, redundant staff training, and fail safe systems. Solutions came to mind to provide a simpler set for the more casual engagement or younger audience and a mini version for those not as careful. And of course, I did put a small reserve set away for me, just for fun…

SUMMARY

With my LEGO® project winding to a close I couldn’t help thinking what’s next? Is my brief LEGO® encounter over? What else is there to do? What other LEGO® lessons are in store for me ahead? Ideas started coming to mind, maybe I could create a LEGO® space set or start using some of the new pieces I discovered to build new things. I was also reminded of the questions we’re asking at the office, The company isn’t remotely close to being all we could be, what can we do with all the new technology available, incredible staff and resources we have assembled, and hugely powerful systems we’ve created with our plan store, calculators, and TaskCloud system?

There’s more to come, I can assure you that. Follow us on social media for more 2020 LEGO® fun, we have collected a lot to post:

Facebook: https://www.facebook.com/EngineeringExpress/

LinkedIn: https://www.linkedin.com/company/engineering-express

Instagram: https://www.instagram.com/engineeringexpress

I think I’ll go back for the Space LEGO®’s…

NOTE: This site is not a part of LEGO® Inc. Additionally, This site is NOT endorsed by LEGO® in any way. LEGO® is a trademark of LEGO Group. Why did I say this and put all those ® in LEGO®’s? That’s coming soon, there’s history there too, I’m not taking any chances.