The term lag bolt implies a large diameter fastener with a bolt head square or hexagonal head, and the term lag screw indicates a fastener with a wood screw tread. Both terms refer to the same type of fastener and are relatively large diameter fasteners. The National Design Specification for Wood Construction (NDS) refers to these fasteners as lag screws.

Lag bolts are used when loads are of relatively large magnitude need to be transmitted through a joint and when an excessively long bolt would be required to make a connection or when one side of a through bolted connection may be inaccessible. They also can be especially effective when withdrawal loads of large magnitude are anticipated.

As PER 2015 NDS Commentary section C12.5.1.3: “Avoidance of heavy or medium suspended loads below the neutral axis of a beam was added as a result of several reported field problems involving glued laminated timber beams subject to a line of concentrated loads applied through bolted hangers or ledger strips attached in the tension zone or at the bottom edge of the beam. Concentrated loads less than 100 pounds and spaced more than 24 inches apart may be considered a light load condition.”

The methods of installation for lag screws and wood screws are also different. Because of their large size, lag bolts are installed with a wrench, and wood screws are usually installed with a screwdriver.

Lags In Use

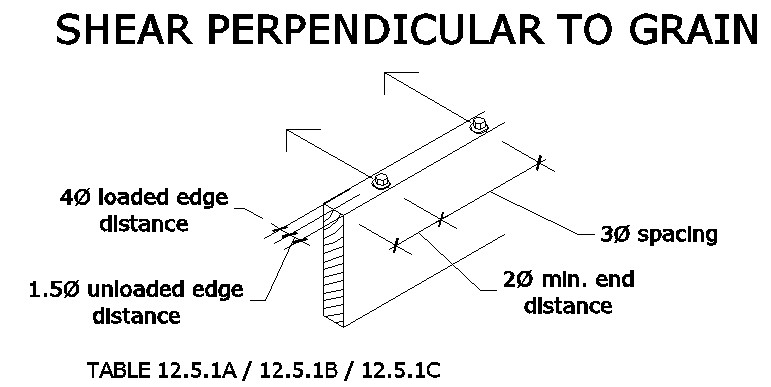

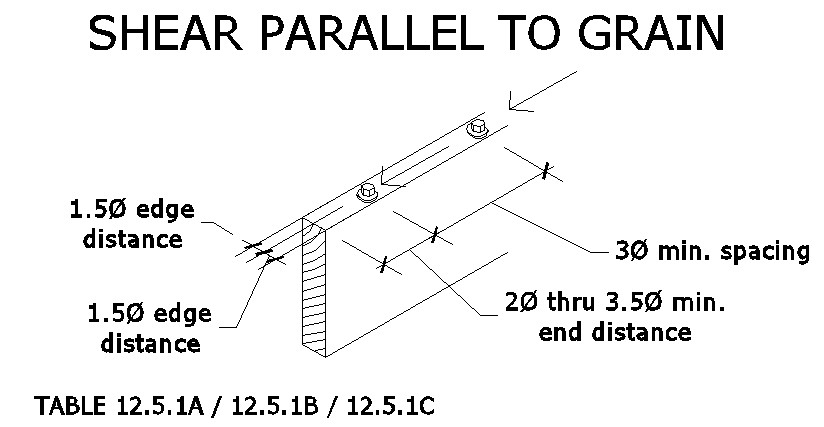

Using lag screws through the sheathing into multi-ply wood columns is always a challenger as we can’t exert great control over the location of the fasteners in relation to wood edge and end distances which dictates the application of this fastener as per NDS tables 12.5.1A, 12.5.1C and 12.5.1E minimum requirements.

With large diameter bolts there is a concern that splitting of the wood member may occur before redistribution of stresses to less highly loaded bolts can occur.

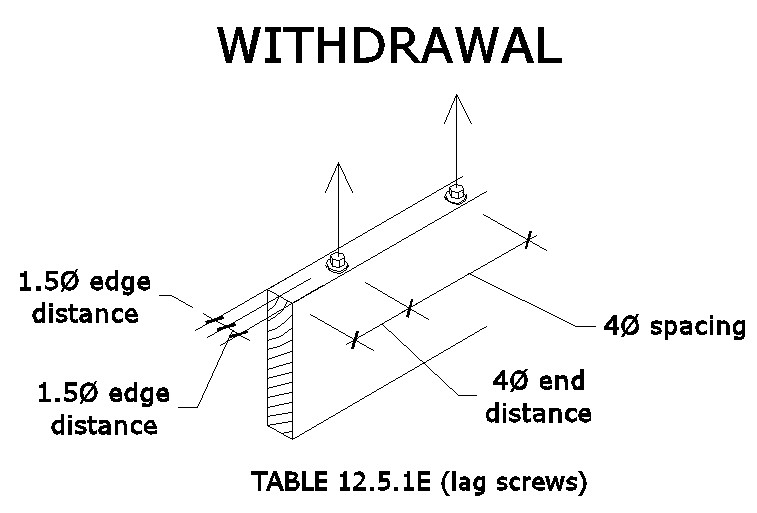

The condition below applies for lag bolts in tension into a 2x narrow face and table 12.5.1E calls out for 1.5 times the fastener diameter for minimum edge distance and 4 times the fastener diameter for minimum end distance. In this case our ½” diameter lag screw requires ¾” edge distance and both can be used.

For lag bolts in shear with loads parallel to grain into a 2x narrow face, table 12.5.1C refers to the same 1.5 times the fastener diameter for minimum edge distance and 2 to 3.5 times the fastener diameter for minimum end distance as per table 12.5.1A. Again, for a ½” diameter lag screw, it will be required ¾” minimum edge distance and both therefore can be used.

Now the problem becomes when the same lag bolt above is loaded perpendicular to the grain. Table 12.5.1C states that the loaded edge shall have a minimum of 4 times the fastener diameter which in this case for ½” lag bolt will be 2 inches (1 ½ inches for 3/8” lag bolt) exceeding the ¾” available if you could get the fastener centered into 2x narrow face.

The loaded and unloaded edges are determined by examining the force on the beam (stud in this case) at the fastener. The loaded edge is the edge toward which the force acts and the unloaded edge is the opposite edge.

For More Information

2015 NDS has provided more specifics for end distance, edge distance and fastener spacing requirements in narrow edge of cross laminated timber but no reduction factors have been proposed yet for this condition when 3/8” lag screws are loaded perpendicular to the grain on a narrow face of a 2x wood member neither provide specific guidance on edge distance requirements for loads applied at angles other than 0° and 90°.

In this case for instance a wood ledger attached to vertical wood studs facing lateral loads from the diaphragm system would require a different approach that’s outside the scope of this article.

Contact Us with your wood connection needs to discuss our innovative engineering solutions.

References

2015 NDS National Design Specification for Wood Construction with Commentary

Design of Wood Structures by Donald E. Breyer, Kenneth J. Fridley, Kelly E. Cobeen and David G. Pollock

Wood Engineering and Construction Handbook by Keith F. Faherty and Thomas G. Williamson

Article by Andre Lopes, Project Designer

For informational purposes only. Consult a licensed PE for any wood/connection needs.

Last Update: February 19, 2022