Tek® screws have become an essential tool in construction and manufacturing, valued for their self-drilling capabilities that simplify a variety of projects. These screws eliminate the need for pre-drilling, saving time and effort while ensuring strong, reliable connections. Ideal for applications like metal roofing and steel framing, Tek® screws deliver durable, high-performance results, making them the go-to solution for professionals.

In this article, we’ll take a closer look at what Tek® screws are, their design features, and why they’re so widely used. We’ll also compare different types of Tek® screws, including their sizes, head styles, and the best uses for each, so you can better understand how to choose the right one for your projects.

What Are Tek® Screws?

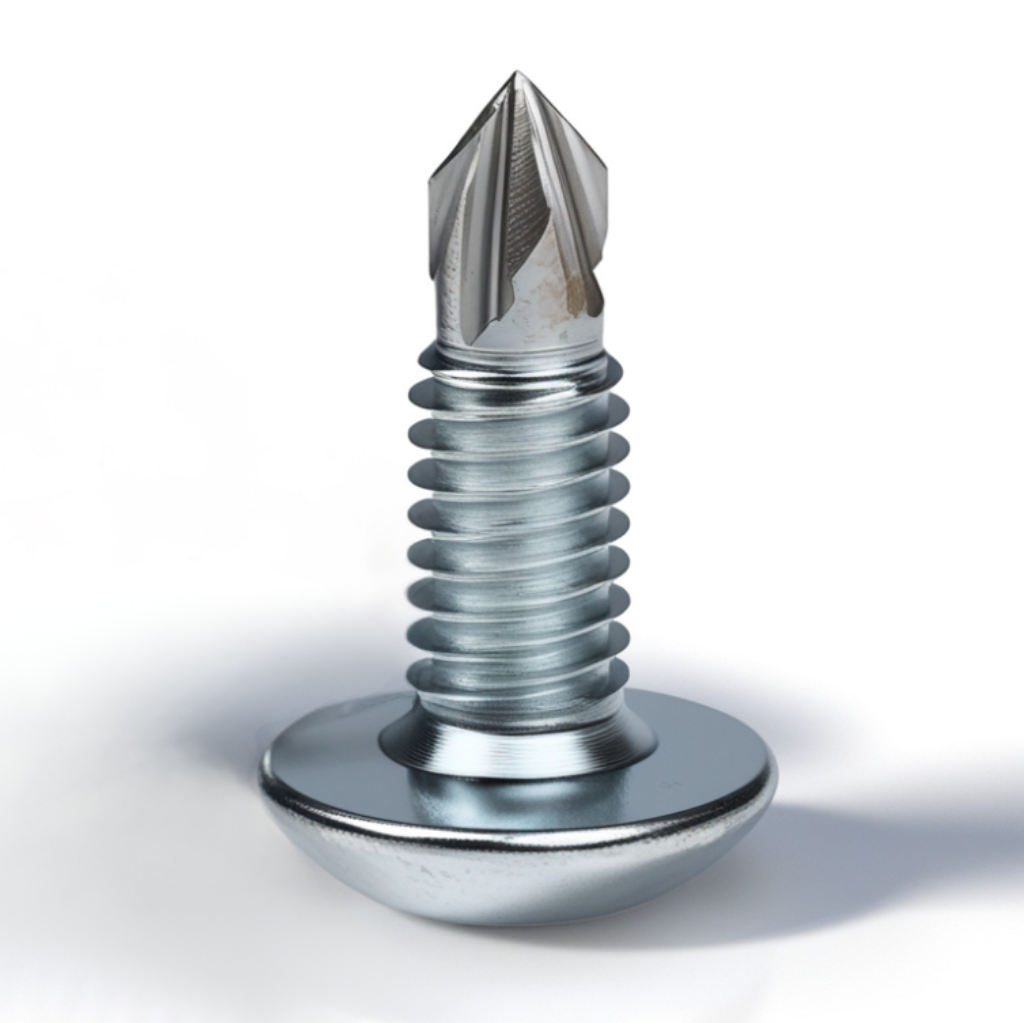

Tek® screws are a type of self-tapping fastener with a unique design that allows them to drill their own hole as they are driven into materials. The small carving at the end of their tip, known as a drill bit, enables these screws to cut through various materials without the need for pre-drilling, streamlining the fastening process. It’s important to note that “Tek® screws” refers specifically to a brand of self-drilling screws. While they are commonly used as a generic term in the construction industry, designers and contractors should specify “self-drilling screws” or “sheet metal screws” in general contexts to include other brands.

Tek® screws are primarily used for metal-to-metal applications, although there is a specialized version, the reamer Tek® screw, designed specifically for wood-to-metal applications. Contractors often use these screws for joining metal-to-metal and, in certain cases, wood-to-metal. There are different drill points available depending on the material thickness, with the Tek® 5 (sometimes called a “beambuster”) being one of the longest and most powerful options. These screws allow users to fasten materials together without pre-drilling, making them an essential tool for many construction and manufacturing projects.

Standard self-drilling screws, including Tek® screws, are not designed for typical metal-to-wood applications. The drill bit creates a hole that is nearly the same size as the screw’s threaded portion, which prevents the threads from tapping into the wood securely. However, some screws, especially those used in roofing applications, feature a tiny drill bit (usually a #1 drill bit). This smaller hole allows the threads to engage properly, providing a strong hold in both metal and wood materials.

Design Characteristics of Tek® Screws

Sizes and Head Styles

Tek® screws come in a wide range of sizes, from smaller #6 diameter screws to larger #12 diameter screws, providing flexibility for various applications. The size of the screw, as well as its head style, determines which type you need for your specific project. Common head styles include the hex washer head, ideal for heavy-duty metal installations, and the modified truss head, which offers a slightly rounded shape for different fastening needs. For flush surfaces, flathead screws are typically used.

Drive Types

The drive type is another important consideration. While many Tek® screws have a Phillips drive, square drive options are gaining popularity for better grip and torque control. For wood-to-metal applications, reamer Tek® screws, which feature wings near the drill bit, are designed to drill through multiple layers and securely fasten materials.

Bit Designs

The bit design of Tek® screws is another critical feature that varies depending on the application. The self-drilling tip is a defining characteristic of Tek® screws, allowing them to drill their own hole as they are driven in. The tips can vary in size and shape depending on the material being drilled. For example, screws used for light-duty metal might have a smaller, finer tip, while screws designed for heavy-duty applications like steel framing may have a larger, more aggressive tip. Reamer Tek® screws come with an additional set of wings that help cut through thicker materials, making them ideal for multi-layer applications.

Screw Materials

- – Zinc-Plated Steel: The most common type, offering very good rust resistance.

- – Weather-Guard Coated (STALGARD®): Protects ferrous metals from rust and corrosion better than many conventional finishes.

- – Stainless Steel: Available in both 18-8 and 410 grades. 18-8 provides excellent corrosion resistance and can be mildly magnetic, while 410 is stronger and magnetic, suitable for chemical environments.

- – Hybrid Screws: These feature a hard steel driver fused at mid-body with an 18-8 stainless steel head. The hard steel driver ensures superior drilling capability, while the 18-8 stainless steel head provides excellent corrosion resistance and durability.

- – Bi-Metal Tek® Screws: These screws combine a carbon steel tip for drilling into tough materials with a stainless steel body for durability and corrosion resistance. They are suitable for a wide range of fastening tasks, offering the necessary strength for challenging applications through varying tip designs, head styles, and sizes.

List of Fasteners

To help you choose the right tek screw for your project, we’ve put together a table that shows some common types of fasteners. You’ll find their key features and typical uses, making it easier to find the perfect match for your needs.

|

Special Purpose Fasteners

|

Head Styles

– Hex Washer Head (HWH): The built-in washer provides a stable bearing surface. These screws can be slotted or unslotted, with unslotted being more common. The length is measured from beneath the head.

– Pan Head: This low-profile head is available with either a Phillips or square drive. The length is measured from beneath the head.

– Flat Head: A countersunk head that sinks into wood for a flush finish. The length is measured from the top of the head.

– Oval Head: Similar to a flat head but with an oval-shaped top for a more finished appearance. The length is measured from the top of the head.

– Flat Head Reamer: A flat top with a Phillips drive, designed to ream wood and then cut steel in one step. The wings ream a clearance hole in thick, low-density materials to prevent thread engagement. When the point penetrates metal, the wings break off and the threads engage normally. The length is measured from the top of the head.

– Round Washer Head: Similar to a hex washer head but with a round head and a Phillips drive. Also known as Metal Lath, K-Lath, or Modified. The length is measured from beneath the head.

– Truss Screws: Known for attaching trusses and similar components. The length is measured from beneath the head.

– Wafer Head: Often called Plymetal screws, these are used to attach plywood to metal. The large wafer head sinks into the plywood and provides a large bearing surface. The length is measured from the top of the head.

– Drywall Bugle Head: Designed for fastening drywall to metal studs. The length is measured from the top of the head.

– Pan Framing: A Phillips drive screw used for attaching studs to tracks in framing. The length is measured from beneath the head.

– Pancake Head: A very low-profile head with a wide bearing surface, ideal for tight spaces. The length is measured from beneath the head.

– Square Trim: Features a square drive and a reduced head size, making it ideal for tight spaces. The length is measured from beneath the head.

Types of Sheet Metal Screws

Tapping screws, especially Type A, are referred to as “sheet metal screws” because one of their first applications was in ventilation ducts made of sheet metal. Over time, though, different types evolved. We’ll cover the common groups: thread forming, thread cutting, thread rolling and self drilling. The combination of point and thread style determines to which group the screw belongs.

In screw designations, the letter “B” indicates spaced threads, as seen in Type AB or B screws. If the “B” is absent, like in Type F, the screw has machine screw threads. Two exceptions exist: Type A, though largely obsolete, still features spaced threads, and Type U metallic drive screws have spaced spiral threads.

Thread-forming screws are designed for use in thin, malleable materials. They have coarse threads and require a properly sized hole. As the screw is driven in, it enlarges the hole by pushing the material outward, often creating burrs. Common thread-forming screws include Types A and AB (standard point) and Type B (blunt point), typically used for sheet metal. Types A and AB are often interchangeable, and sizes range from #2 to 3/8.

For thicker, harder metals, thread-cutting screws are used. These screws have cutting flutes at the tip that act like a tap to create threads as they are driven in. Like taps, they require a correctly sized hole and produce chips. When installed in blind holes (holes that don’t go all the way through), chips accumulate at the bottom, so make sure there’s enough hole depth. In through-holes, chips exit through the other side. Be cautious of metal chips, as they can cause electrical shorts or contaminate lubricants. Type F is a common thread-cutting screw, and since it’s essentially a machine screw, its threads are more closely spaced than those of sheet metal screws. Once a hole is tapped by a thread-cutting screw, it can be replaced by a machine screw of the same size. Common sizes include 4-40 to 3/8-16.

Self-drilling screws, also called Teks®, feature a drill-like tip and spaced threads, similar to sheet metal screws. These screws drill, tap, and fasten in a single operation.

Type U metallic drive screws feature spaced spiral threads and a blunt point. They are forced under pressure into the material and are considered permanent fasteners, unlike other tapping screws that can be removed.

For low-density materials like plastic, particle board, Masonite®, and wood, High-Low thread screws are ideal. The “high” thread is sharp, while the “low” thread is about half the height. These screws reduce driving torque, minimize thread stripping, increase pull-out strength, and reduce the risk of cracking or splitting the material.

Finally, drywall screws are commonly used with sharp point and self-drilling styles. Sharp point screws are for wood and light gauge steel studs, while self-drilling screws are for heavy gauge steel studs. The bugle head design is self-countersinking, helping to resist tearing the drywall paper surface and preventing damage to the gypsum core.

Now that Tek® screws hold no secrets for you, we wish you the best of luck with your upcoming projects! If you have any questions about project design or need engineering assistance, simply click the button below to get in touch with us. Don’t forget to explore our other engineering articles for more valuable insights and tips!

For more detailed information and guidance on handling your future design projects, check out our online design calculators, contact us for site-specific projects, or reach out to us with your inquiries.

Last Update: November 22, 2024

Related Knowledge Base Posts -

- ASCE 7 WIND EXPOSURE CATEGORIES AND HOW EXPOSURE ‘D’ WORKS

- Why are spacing, edge distance, and embedment important for concrete anchors?

- What wind information is required for construction documents?

- Understanding Canopies: Design and Load Considerations

- What’s the dimensional difference between a pipe and a tube?

- Metal Fasteners UNC vs Spaced Thread